Disassembly and Assembly Process of the Screw

(1)Open the machine head and extrude the material in the extruder. After the material is completely extruded, keep the screw idling for at least 5 minutes to prevent residual material inside the screw from affecting screw removal.

(2)Remove the pressure sensor from the machine head and open the side pressure roller simultaneously.

(3)Remove the pins of the extruder: Each pin on the extruder is locked with a clamping nut. Follow these steps for removal: ① Use a hex wrench to remove the nut; ② Screw the pin puller into the pin, then use the pin extractor to remove the pin; ③ Continuously strike the rear end of the pin puller with a sliding sleeve to overcome the pin’s fastening force. Repeat this action until the pin is pulled out. Note: Do not pull the pin extractor toward your body during removal. Sudden pin extraction may cause injury to the operator. Keep a record of the pin arrangement during removal to provide a theoretical basis for pin installation or process problem-solving.

(4)After confirming all pins are removed, disassemble the screw casing, insert the screw ejector, and use the ejector’s threads to push out the screw. Once the splines of the screw are fully disengaged from the extruder, pull the screw out from the machine head. If resistance is significant, extend the inner casing and continue using the screw ejector. For angled screws (especially plunge-type screws), secure a lifting rope to the screw head during ejection to prevent accidental sliding and injury.

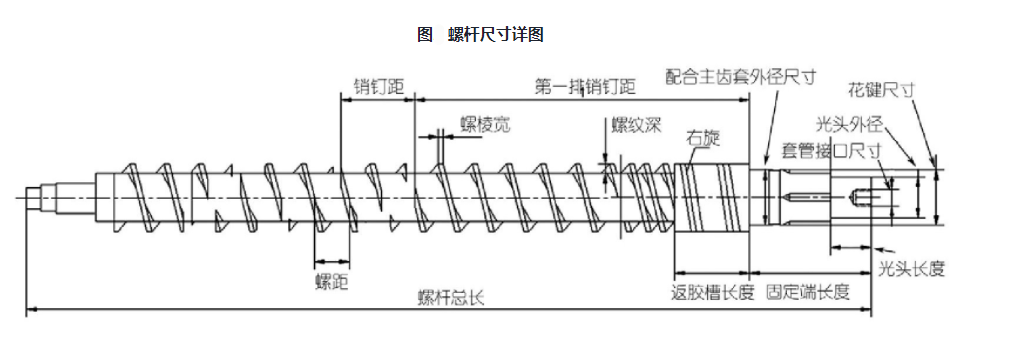

(5)After pulling out the screw, inspect the wear of the screw washer and the mating part with the main gear sleeve. Replace them if necessary.

(6)For a new screw, apply grease to the splines and high-temperature anti-seize oil to the smooth ends. Do not forget to install the screw washer, then carefully slide the screw into the extruder from the machine head side.

(7)Slide the screw’s splines into the spline sleeve of the speed reducer until the screw contacts the front end face of the drive shaft. When assembling the splines, manually rotate the coupling to ensure the screw’s splines smoothly enter the spline sleeve of the output shaft, avoiding local upsetting (i.e., collision) of the spline teeth and the sleeve teeth. If resistance is encountered during installation, identify the cause and eliminate it without using external force. Do not strike the screw. If striking is necessary, first push the screw as far as possible into the drive shaft’s spline sleeve before applying force.

(8)After inserting the screw, use a casing to tension it. Check whether the position of the screw’s blade aligns with the pin groove to ensure each inserted pin does not collide with the screw.

(9)Install the pins according to the pre-recorded pin arrangement diagram and reconnect the screw casing. Note: Ensure the screw casing is well-sealed to prevent water leakage.

(10) Manually rotate the coupling for at least one full revolution to check for significant resistance.

(11)Install the rotary joint and coupling guard.

(12)Close the side pressure roller of the feed seat.

(13) Install the temperature sensor.

引自-顾建.挤出机螺杆拆装难点及解决方法浅析[J].